One of the most common questions asked for in-service inspection and testing is ‘Do I need to PAT test Christmas tree lights’ or ‘How do I PAT Test Christmas tree lights’ and really there are a few factors to consider depending on the environment, users, and construction of the lights themselves.

As with any electrical equipment, it is very important we carry out a thorough visual inspection. Although Christmas tree lights are typically stored away for most of the year, if not stored away safely, damage can occur during storage. We also need to consider the environment in which they are used as they can be used both indoors and outdoors and can also be installed in environments where you have the general public, young children and even the vulnerable.

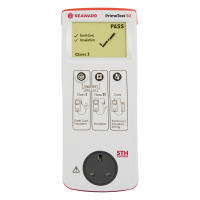

Nowadays, almost all modern lights you come across will either be Low Voltage or Class II.

Class 0 equipment has no basic insulation around the live conductors. There is no supplementary insulation or earthing of exposed parts. In most cases Class 0 equipment should fail visual inspection and be removed from service

So how you go about testing them will all depend on the equipment construction itself. Most lights will be either low voltage (battery powered/LED) or Class II running off transformers. Most won’t have earthing for fault protection or have any exposed conductive parts to carry out insulation resistance testing, so in most scenarios a thorough visual inspection is all you can do.

When carrying out a thorough visual inspection we would check all the cabling, the fittings, and the plug top/battery compartment for any signs of damage or over-heating.

If the lights are Class I and has an earth for fault protection, then we would treat them as we would any Class I electrical equipment carrying out as a minimum a thorough visual inspection (as above), earth continuity test, insulation resistance test and then finally a function check. If the lights are Class II with exposed conductive parts, then as a minimum, we would be carrying out a thorough visual inspection (as above), insulation resistance test and then finally a function check.

Other considerations when installing Christmas Tree lights:

Make sure they are not causing a trip hazard

That they are not secured/bent to tightly around objects

Not wrapped to close together (can cause excess heat)

Not to be used with multiway adaptors

If used with extension leads, the extensions themselves are to be PAT Tested and not overloaded and must be fully wound out

Only use lighting outdoors if specified its safe to do so by the manufacturer

Sign up to our Newsletter.

Stay up to date with the latest industry and product news, as well as our free educational content such as webinars and our expert guides.

Close